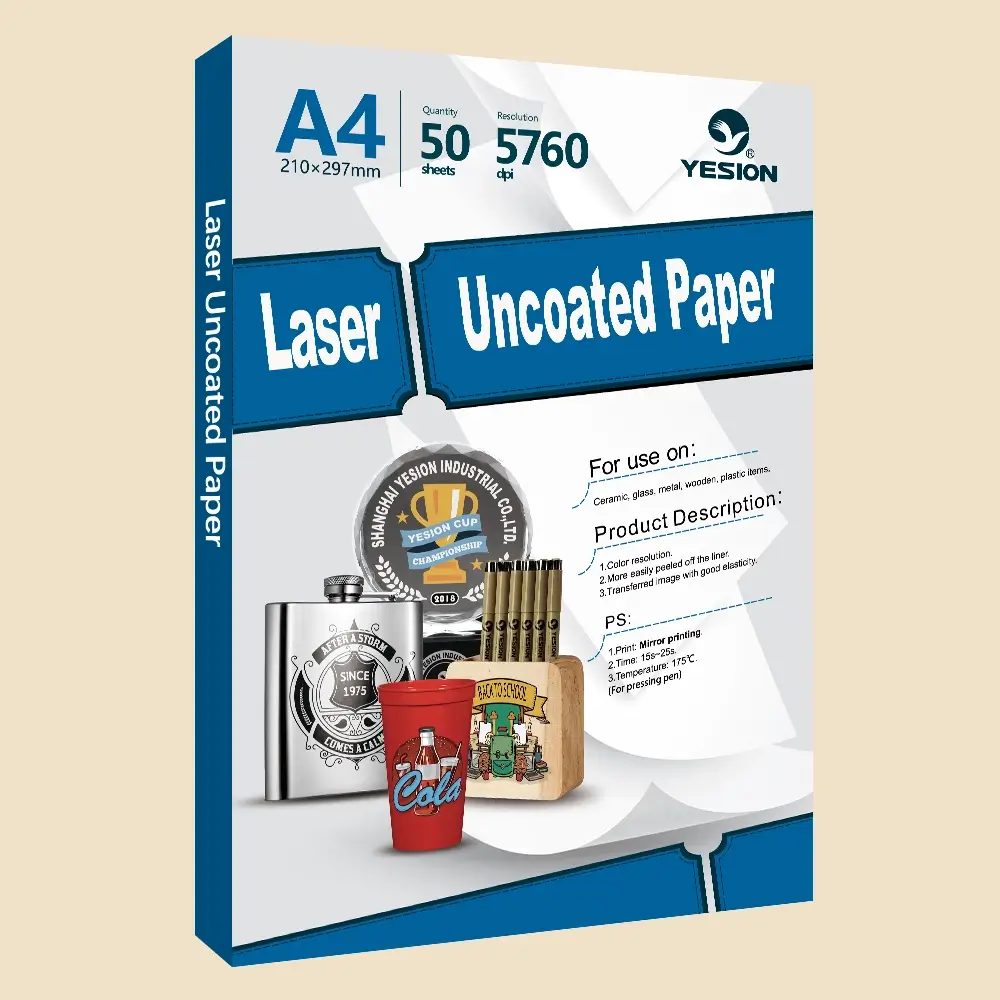

Specificaltions

| Name | Laser uncoated paper |

| Size | A4 |

| Package | 50sheet/pack |

| Print mode | Mirror printing |

| Printer | Low temperature laser printer |

| Transfer time | 15-25s |

| Transfer temperture | 175℃ |

| Peel type | Cold peel |

Opertation and Video

1. First type the pattern that you need to print on the computer , select the laser uncoated paper, print in the laser printer

2. Cut the part we need, fix the paper with pattern on the transfer pen with high temperature tape

3. Place the pen with the transfer paper in the groove of the pen heat press machine (the side to be transferred)

4. Adjust the pressure, set the transfer parameters 175 degrees Celsius, 15 seconds

5. Transfer is complete, Cold peel.

Attention:

1. Select the horizontal flip (image) before printing(mirror printing)

2. General printer selection: print quality for the photo type paper ,Please choose (thick paper) or label paper

3. Printing parameters:

Ceramic metal glass: 160 degrees, 3 minutes, so after cooling and then tear, it is best to use a thin silicone pad, to ensure that

will not crush, the temperature can be increased according to the appropriate thickness of the silicone pad

Leather wood: 160 degrees ,1 minute after the transfer, in 1/5 seconds heat tearing

Pen: 175 degrees, 25 seconds, Recommended transfer area within 5 * 1.3cm

Different products will have a little bit of error, the best way is to test their own a few times, test a most appropriate temperature.

Application

Laser Uncoated Transfer Paper is widely used on acryllic sheet, acryllic award plaque, acryllic pen, glass mug, ceramic mug, stainless thermos cup aluminum sheet, ceramic tile, leather wallet promotional pens, plastic, ceramic mugs and so on.