2025 Spring Festival Holiday Notice

2025-01-24

What can you do with cold laminating film?

2025-02-04Both hot and cold laminating have their distinct advantages, and the best option depends on the specific needs of your project. To help you choose the right method, we’ll compare the two in terms of their benefits, applications, and limitations.

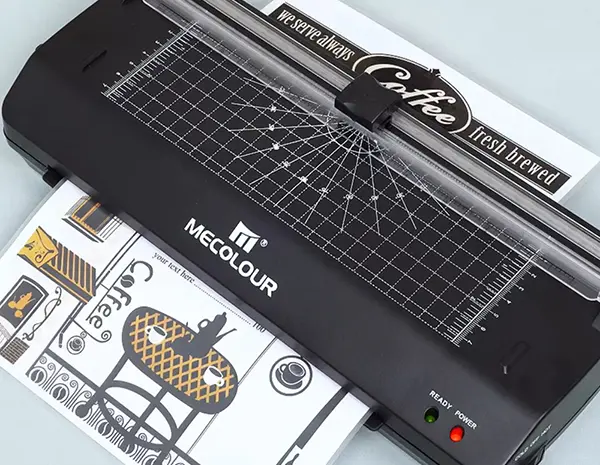

What is Hot Laminating?

Hot laminating involves using heat to melt a layer of adhesive onto the surface of your material. A hot laminating machine heats up a film that contains a thermoplastic adhesive, which bonds to your item when pressure is applied.

Advantages of Hot Laminating

Stronger Bond

Hot lamination forms a durable, long-lasting bond between the film and your material, offering excellent protection against wear and tear.

Variety of Film Types

Hot laminating is suitable for different types of laminating films, such as gloss, matte, or textured finishes. This gives you flexibility depending on the finish you desire.

Smooth Finish

The application of heat ensures that the film adheres smoothly without wrinkles or bubbles, leaving a professional-quality finish.

Ideal for Larger Jobs

Hot lamination is fast and efficient, making it ideal for high-volume lamination. It’s the go-to method for businesses or projects that require consistent, high-quality results.

Durability

Hot-laminated materials are more resistant to scratches, tears, and moisture, making them ideal for protecting important documents, photographs, and signs.

Hot Laminating

Limitations of Hot Laminating

Heat Sensitivity

Hot lamination may not be suitable for items that are sensitive to heat, such as photographs or certain types of paper that could warp or degrade under high temperatures.

Requires Equipment

Hot lamination requires a laminating machine, which could be an initial investment if you don’t already own one.

Time-Consuming

Although faster than some manual methods, it still requires time for the machine to heat up and process each sheet.

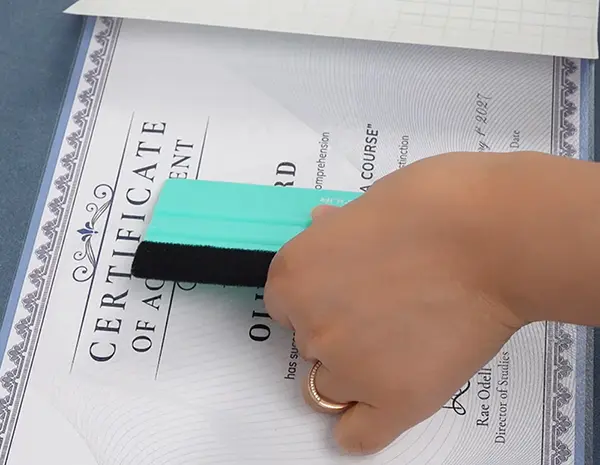

What is Cold Laminating?

Cold laminating involves using a pressure-sensitive adhesive applied to the back of a protective film. No heat is involved in the process, and you typically apply the film manually or with a cold laminating machine.

Advantages of Cold Laminating

No Heat Required

Cold laminating is perfect for heat-sensitive materials like photographs, inks, or delicate documents that could be damaged by heat.

Simple to Use

Unlike hot laminating, cold laminating does not require a machine in most cases. You can apply it by hand, making it easy to use for small-scale projects or in areas without access to a laminating machine.

Cost-Effective

Cold laminating is generally more affordable because you don’t need specialized equipment. You can often use just a roller or squeegee for manual applications.

Quick and Convenient

The process is fast since there is no need to wait for heat to build up. It’s particularly useful when you need to laminate a small batch of documents or do a quick fix.

Less Risk of Warping

Since no heat is applied, there is no risk of warping or damaging thin or fragile materials during the process.

Cold Laminating

Limitations of Cold Laminating

Weaker Bond

The adhesive used in cold lamination is not as durable as hot lamination, which means it may peel off or wear down more quickly, especially on high-use items.

Limited Finish Options

Cold lamination typically provides fewer options for finishes. You can generally choose between matte or glossy, but it lacks the texture variety that hot lamination offers.

Potential for Air Bubbles

If not applied correctly, cold laminating can lead to air bubbles or wrinkles. A careful and steady hand is needed to apply the film smoothly.

Not Suitable for Large-Scale Projects

Cold lamination is less efficient for large batches, especially when uniformity and speed are important. It’s better suited for individual or small-scale jobs.

Hot vs. Cold Laminating: Which is Better?

The choice between hot and cold laminating comes down to the specific needs of your project. Here’s a breakdown:

| Criteria | Hot Laminating | Cold Laminating |

| Heat Sensitivity | Not suitable for heat-sensitive materials | Ideal for heat-sensitive materials |

| Adhesion Strength | Strong, durable bond | Weaker bond, can peel over time |

| Finish Options | Gloss, matte, textured | Gloss, matte, textured |

| Equipment Required | Requires a laminating machine | Can be done by hand or with a simple tool |

| Ease of Use | Requires some practice with the machine | Easy and quick to apply manually |

| Cost | Higher initial cost for machine and film | More cost-effective, no machine needed |

| Best For | High-volume, professional applications | Small, personal projects or delicate items |

When to Choose Hot Laminating

- You’re working with larger, more durable materials that need extra protection.

- The project involves bulk lamination and requires speed.

- You need a high-quality, long-lasting bond for professional presentations, posters, or documents.

When to Choose Cold Laminating

- You need a simple, quick solution without access to a laminating machine.

- You’re working with heat-sensitive materials like photographs or delicate artwork.

- You’re on a budget or working on a small-scale project.

- You prefer a manual, hands-on approach to lamination.

Both hot and cold laminating have their own strengths, and the best choice depends on the specifics of your project. If you need a high-quality, durable finish and are working with larger quantities, hot laminating is the better option. However, if you’re working with heat-sensitive materials, have a smaller project, or need a more cost-effective solution, cold laminating can offer a practical alternative.