Can You Use Infusible Ink on Sublimation Blanks?

2024-07-30

Everything Need to Know About Temporary Tattoo Printer Paper

2024-08-06Infusible Ink transfer sheets have revolutionized the world of custom shirt design, offering a professional-quality finish that seamlessly blends with the fabric. Yesion, as experts in the digital printing industry, we’ve been testing this technology to see how it can transform the way DIY enthusiasts personalize their shirts.

What is Infusible Ink?

Infusible Ink is a unique heat transfer material that, unlike traditional iron-on transfers, becomes part of the fabric itself. This revolutionary technology results in designs that won’t peel, crack, or wash away over time, maintaining their vibrancy and integrity even after multiple washes.

How Infusible Ink Differs from Traditional Heat Transfer Vinyl

While heat transfer vinyl sits on top of the fabric, Infusible Ink actually dyes the fibers of the shirt. This creates a more durable and professional-looking result that feels soft to the touch, without adding any extra layer or weight to the garment.

Benefits of Using Infusible Ink Transfer Sheets for Shirts

Exceptional Durability: Infusible Ink designs withstand repeated washing and wear, maintaining their quality over time.

Professional Finish: The end result looks and feels like it was professionally screen-printed, giving your shirts a high-end appearance.

Vibrant Colors: Infusible Ink offers rich, vivid colors that truly pop on the fabric.

Soft Feel: Unlike some traditional transfers, Infusible Ink doesn’t create a stiff or plasticky feel on the shirt.

Versatility in Design: With a wide range of colors and patterns available, the creative possibilities are endless.

Choosing the Right Materials

Compatible Fabrics

For best results, Infusible Ink works optimally on polyester or polyester-blend fabrics. The higher the polyester content, the more vibrant and long-lasting your design will be. This makes it ideal for performance wear, athleisure, and modern fashion trends that often incorporate synthetic fabrics.

Selecting the Right Transfer Sheets

Companies like Yesion offer a wide variety of Infusible Ink transfer sheets, including solid colors, patterns, and even specialty finishes. When choosing your transfer sheets, consider the following:

Color Range: Select sheets that complement your design and the shirt color.

Pattern Options: Explore unique patterns to add texture and interest to your designs.

Sheet Size: Ensure the sheet size is appropriate for your intended design and shirt size.

Compatibility: Verify that the transfer sheets are compatible with your heat press or EasyPress machine.

infusible ink shirts

The Infusible Ink Transfer Process for Shirts

Design Creation: Use design software to create or modify your artwork, ensuring it’s mirrored if it contains text or directional elements.

Material Preparation: Pre-wash your shirt to remove any sizing or residues that might affect the transfer process.

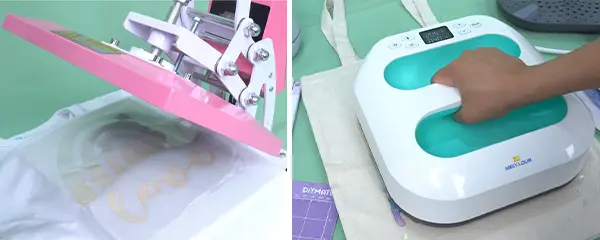

Heat Press Setup: Preheat your heat press or EasyPress to the correct temperature (typically around 385°F or 196°C) for optimal results.

Transfer Application:

Place a protective sheet inside the shirt to prevent bleed-through.

Position your Infusible Ink design face-down on the shirt.

Cover with butcher paper or a protective sheet.

Apply firm, even pressure for the recommended time (usually 40-60 seconds).

Cooling and Revealing: Allow the transfer to cool completely before carefully peeling away the backing to reveal your design.

Tips for Success with Infusible Ink Shirts

Temperature and Pressure: Ensure your heat press is set to the correct temperature and that you apply even pressure across the entire design.

Use a Lint Roller: Before applying your transfer, use a lint roller on the shirt to remove any dust or debris that could interfere with the transfer process.

Test Runs: Always do a test run on a scrap piece of fabric before committing to your final shirt.

Layer Strategically: For multi-color designs, plan your layers carefully, applying lighter colors first and darker colors on top.

Avoid Overheating: Follow the recommended pressing time to prevent color shifting or fabric damage.

Caring for Infusible Ink Shirts

To maintain the quality of your Infusible Ink shirts:

Wash inside out in cold water.

Avoid using harsh detergents or bleach.

Do not iron directly over the design.

Air dry or tumble dry on low heat.

Infusible Ink transfer sheets have truly transformed the landscape of custom shirt design. With their durability, professional finish, and ease of use, they offer an excellent solution for both personal projects and small businesses looking to create high-quality custom apparel. By following the tips and techniques outlined in this guide, you’ll be well-equipped to produce stunning, long-lasting designs that stand out from the crowd.

As the technology continues to evolve, we can expect even more innovations in the world of Infusible Ink, opening up new possibilities for creative expression and custom apparel design. Whether you’re a hobbyist or a professional, Infusible Ink transfer sheets are a valuable tool in your arsenal for creating eye-catching, professional-quality custom shirts.