Everything You Need to Know About Infusible Ink Transfer Sheets

2024-01-03

Exploring Types of Printable Sticker Vinyl

2024-01-09Infusible Ink Transfer Sheets have revolutionized the world of crafting with their ability to create vibrant and permanent designs on various surfaces. To unlock the full potential of these innovative transfer sheets, mastering the art of using a heat press is essential. YESION, as an expert in digital printing industry, will provide you with expert tips and techniques to ensure flawless applications of Infusible Ink Transfer Sheets using a heat press machine.

Benefits of Using a Heat Press with Infusible Ink

Vibrant and Long-Lasting Designs

The heat press activates the infusible ink, resulting in designs that not only pop with vibrancy but also withstand the test of time.

Seamless Integration with Fabric and Surfaces

Infusible Ink seamlessly integrates with fabrics and surfaces, creating a smooth, durable, and virtually peel-proof finish.

Getting Started with Heat Press and Infusible Ink

Essential Tools and Materials

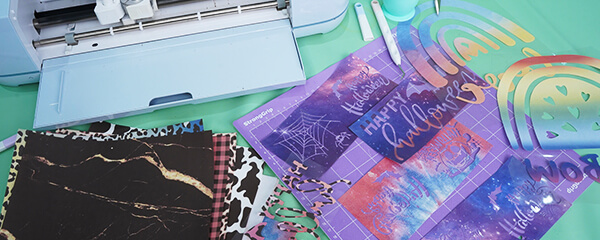

Gather essential tools like a heat press machine, compatible infusible ink transfer sheets, heat-resistant tape, and a reliable cutting machine.

Choosing the Right Infusible Ink Transfer Sheets

Selecting high-quality transfer sheets is crucial for achieving professional results. Consider the compatibility with your chosen fabrics and surfaces.

Step-by-Step Guide to Using a Heat Press with Infusible Ink

Preparing the Heat Press Machine

Follow the manufacturer’s guidelines to set up and preheat your heat press machine to the recommended temperature.

Proper Placement of Infusible Ink Transfer Sheets

Carefully place the transfer sheets on your chosen surface, ensuring even and secure placement.

Temperature and Time Settings

Adjust the heat press settings based on the infusible ink and surface specifications for optimal results.

Peeling and Finishing Techniques

Master the art of peeling the transfer sheet post-application and employ finishing techniques to enhance the overall look.

How to use arrival infusible ink transfer sheet?

Tips for Using a Heat Press with Infusible Ink Transfer Sheets

1. Select the Right Heat Press Machine

Choosing the right heat press machine is crucial for successful Infusible Ink applications. Look for a heat press that offers precise temperature control and even heat distribution. Additionally, ensure that the heat press has sufficient pressure adjustment capabilities for different materials and thicknesses.

2. Preheat Your Heat Press

Before applying the Infusible Ink Transfer Sheet, preheat your heat press machine to the recommended temperature for the specific material you are working with. This step ensures that the heat press is at the optimal temperature for ink transfer and ensures consistent and vibrant results.

3. Prepare Your Transfer Sheet and Material

Trim your Infusible Ink Transfer Sheet to the desired size and ensure that the design is facing up. Place a piece of butcher paper or a heat-resistant mat on the heat press platen to protect it from any potential ink bleed-through. Position your fabric or other compatible material on top of the butcher paper or mat.

4. Proper Placement and Alignment

Carefully place your trimmed Infusible Ink Transfer Sheet on the desired area of your material. Take time to align the design precisely, ensuring that it is straight and centered. Secure the transfer sheet in place using heat-resistant tape to prevent any movement during the pressing process.

5. Apply Even Pressure

Once your material and transfer sheet are properly aligned, close the heat press machine and apply even pressure. Refer to the manufacturer’s guidelines for the recommended pressure settings based on the material you are using. Applying even pressure ensures that the ink transfers uniformly and results in a flawless design.

6. Timing and Temperature Control

Timing and temperature control are crucial factors in achieving optimal Infusible Ink transfers. Refer to the instructions provided by the transfer sheet manufacturer for the recommended time and temperature settings. Set the heat press machine accordingly and use a timer to ensure accurate timing. Avoid overexposure to heat, as it can result in color fading or distortion.

7. Post-Pressing Care

After the pressing process is complete, carefully remove the material from the heat press machine. Be cautious as it will be hot. Allow the material to cool completely before handling or moving it. This cooling period is essential for the ink to set and bond with the material, ensuring a permanent design.

8. Wash and Care Instructions

Infusible Ink designs are permanent and will withstand multiple washes. However, it’s important to follow the recommended washing and care instructions provided by the transfer sheet factory. Generally, machine washing with cold water and gentle detergent is recommended. Avoid using bleach or fabric softeners, as they can affect the vibrancy and longevity of the design.

Mastering the use of a heat press machine with Infusible Ink Transfer Sheets opens up a world of creative possibilities for crafters. By following these expert tips and techniques, you can achieve flawless and vibrant designs on various materials. If you want to get high-quality infusible ink transfer sheets and heat press machines, please feel free to contact us for a quote, we provide you with professional products for your business.

Related:

Everything You Need to Know About Infusible Ink Transfer Sheets