Double-Sided Photo Paper in Advertising: Print Ads that Pop

2024-04-12

Water Transfer Paper Printer Compatibility

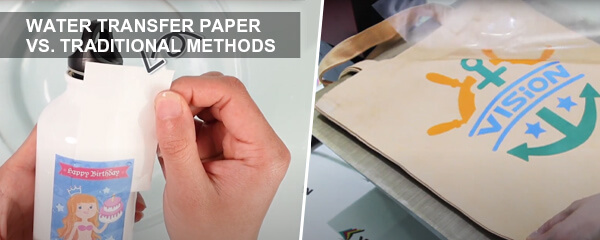

2024-04-19When it comes to transferring designs onto various surfaces, two common methods stand out: water transfer paper and traditional transfer methods. Each method has its advantages and limitations, making it essential to understand their differences to choose the right one for your project. In this article, we’ll conduct a comparative analysis of water transfer paper versus traditional methods to help you make an informed decision.

Water Transfer Paper: Overview

Water transfer paper, also known as waterslide decal paper, is a specialized paper coated with a water-soluble adhesive layer. Designs are printed onto the paper using an inkjet or laser printer, then transferred onto the desired surface using water as a medium. Water transfer paper is commonly used for customizing ceramics, glassware, and other smooth surfaces.

How to use yesion inkjet clear water decal paper?

Advantages of Water Transfer Paper

Easy to use with standard inkjet or laser printers.

Allows for precise and detailed designs.

Suitable for smooth surfaces such as ceramics and glass.

Can be sealed for added durability and protection.

Traditional Transfer Methods: Overview

Traditional transfer methods involve applying a transfer medium, such as heat transfer vinyl or transfer tape, onto the surface of the desired object. Designs are either printed onto the transfer medium using a specialized printer or cut from adhesive vinyl using a cutting machine. Traditional transfer methods are commonly used for customizing apparel, signage, and promotional items.

Advantages of Traditional Transfer Methods

Versatile, suitable for a wide range of surfaces including fabric, wood, and metal.

Durable and long-lasting, especially when using heat transfer vinyl.

Can be used for both single-color and multi-color designs.

Offers greater flexibility in terms of design size and complexity.

Comparative Analysis

Ease of Use

Water Transfer Paper: Relatively easy to use with standard inkjet or laser printers, but requires careful handling during the transfer process.

Traditional Methods: Requires specialized equipment such as a cutting machine or heat press, but offers more flexibility in terms of application and customization.

Surface Compatibility

Water Transfer Paper: Best suited for smooth surfaces such as ceramics, glass, and plastic.

Traditional Methods: Can be used on a wide range of surfaces including fabric, wood, metal, and more.

Durability

Water Transfer Paper: Can be sealed for added durability, but may not withstand heavy wear and tear.

Traditional Methods: Offers greater durability, especially when using heat transfer vinyl, making it suitable for apparel and other items subjected to frequent use.

Design Complexity

Water Transfer Paper: Allows for precise and detailed designs, but may be limited in terms of size and complexity.

Traditional Methods: Offers greater flexibility in terms of design size and complexity, making it suitable for intricate and multi-color designs.

In conclusion, both water transfer paper and traditional transfer methods offer unique advantages depending on the specific requirements of your project. Water transfer paper is ideal for applications that require precise and detailed designs on smooth surfaces, while traditional methods offer greater versatility and durability, especially for apparel and items subjected to heavy wear and tear. By understanding the differences between these two methods, you can choose the one that best suits your needs and achieve professional-quality results.