Achieving Stunning Results with Dark T-Shirt Transfers

2023-12-05

Differences of Glossy, Matte, and Satin Finishes in Self-Adhesive Photo Paper

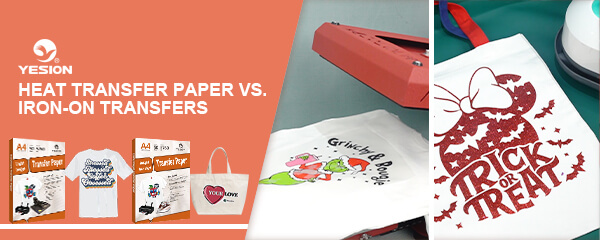

2023-12-12Heat transfer paper and iron-on transfers are two popular methods used for creating custom designs on fabrics. Whether you’re a DIY enthusiast or a small business owner, it’s important to understand the differences between these two methods and choose the right one for your specific projects.

Understanding Heat Transfer Paper

Heat transfer paper is a specialty paper that is coated with a heat-activated adhesive on one side.

Heat press transfer paper works by using heat and pressure to transfer the ink from the paper onto the fabric. The process involves printing the design onto the transfer paper using a compatible printer. Once the design is printed, it is placed face-down (face-up) onto the fabric and heat is applied using a heat press. The heat causes the ink to transfer onto the fabric, resulting in a vibrant and durable design.

Different Types of Heat Transfer Paper

Heat transfer paper comes in various types, each designed for specific applications.

For fabrics of different colors:

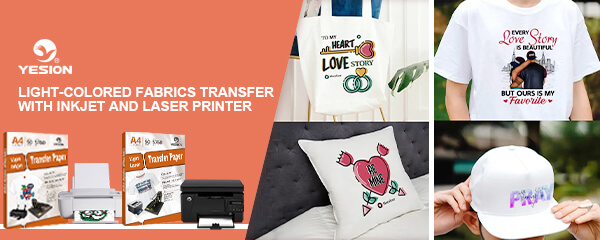

Light-colored Transfer Paper: This type of paper is specifically designed for light-colored fabrics. It works by transferring the ink onto the fabric, creating a vibrant and long-lasting design.

Dark-colored Transfer Paper: Dark-colored transfer paper is suitable for darker fabrics. It incorporates a white background, ensuring that the colors of the design appear vividly on the fabric.

For different printers:

Inkjet vs. Laser Transfer Paper: Heat transfer paper is further categorized into inkjet and laser transfer paper. Inkjet transfer paper is compatible with inkjet printers, while laser transfer paper is designed for laser printers. It’s important to choose the appropriate type based on the printer you have.

Advantages of Heat Transfer Paper

Versatility: Heat transfer paper can be used on a wide range of fabric materials, including cotton, polyester, and blends. It allows for vibrant and detailed designs to be transferred onto fabric.

Ease of Use: Using heat transfer paper is relatively simple. Once the design is printed on the paper, it is a matter of applying heat and pressure to transfer the image onto the fabric.

Affordability: Heat transfer paper is generally more affordable compared to other methods of customizing fabric, such as screen printing or embroidery.

How to use Yesion Inkjet Luminous Dark Transfer Paper with a heat press?

Disadvantages of Heat Transfer Paper

Limited Durability: Heat transfer paper designs may not be as durable as other methods of customization. They can fade or crack over time, especially with frequent washing and drying.

Restrictions on Fabric Color: Heat transfer paper works best on light-colored fabrics. It may not yield satisfactory results on dark or heavily textured fabrics.

Lack of Breathability: The heat transfer paper can create a layer on the fabric, reducing its breathability. This can be a concern when using it on garments that need to be comfortable to wear.

Exploring Iron-On Transfers

On the other hand, iron-on transfers involve applying pre-made designs to fabrics using heat from an iron. It is used in the field of crafting and DIY projects. Create custom t-shirts, tote bags and other personalized items.

Types of Iron-On Transfer Paper

Light vs. Dark Transfer Paper for Inkjet Printer

Iron-on transfer paper for inkjet comes in two main types: light transfer paper and dark transfer paper. The choice between the two depends on the color of the fabric you plan to transfer the design onto.

Light Transfer Paper: This type is designed for light-colored fabrics, such as white or pastel shades. It allows the colors in the design to show up vividly on the fabric.

Dark Transfer Paper: Dark transfer paper is specifically designed for dark-colored fabrics, such as black or navy blue. It has a white background that helps the colors in the design stand out on darker fabrics.

Advantages of Iron-On Transfer paper

Ease of Use: One of the biggest advantages of iron-on transfers is their simplicity. All you need is an iron, the transfer paper, and the fabric you want to apply the design to. The process is straightforward and can be easily done at home without any specialized equipment.

Cost-Effective: Iron-on transfers are a cost-effective way to create custom designs on fabrics. Compared to other methods like screen printing or embroidery, iron-on transfers require minimal investment. Transfer papers are widely available at affordable prices, and you can create multiple designs using a single sheet.

Versatility: Iron-on transfers can be used on a variety of fabrics, including cotton, polyester, and blends. This versatility allows you to create designs on different types of clothing, accessories, and home decor items. Whether you want to personalize a t-shirt, a tote bag, or a pillowcase, iron-on transfers can be easily applied.

Customization: Iron-on transfers offer a high level of customization. You can design your own artwork, use images or graphics from the internet, or even print photographs onto transfer paper. This gives you the freedom to express your creativity and create unique designs that reflect your personal style.

Quick Results: Iron-on transfers provide instant results. Once you have applied the transfer paper to the fabric and ironed it, the design is ready to be displayed or worn. There is no drying time or waiting period involved, making it a convenient option for those who need quick turnaround times.

This video is about how to use dark iron on heat transfer paper

Disadvantages of Iron-On Transfers

Durability: While iron-on transfers are generally durable, they may not withstand heavy use and frequent washing as well as other methods like screen printing or embroidery. Over time, the design may start to fade or peel off, especially if the garment is subjected to frequent washing or high heat.

Limited Detail and Color Options: Iron-on transfers may not be suitable for designs with intricate details or a wide range of colors. The quality of the final print depends on the resolution and quality of the image used on the transfer paper. Fine lines and small details may not transfer accurately, leading to a loss of clarity in the design.

Sensitivity to Heat: Iron-on transfers are sensitive to heat, which means that certain fabrics cannot be used with this method. Fabrics like nylon or spandex can be easily damaged or distorted when exposed to the high temperatures required for the transfer process. It is essential to check the compatibility of the fabric with iron-on transfers before attempting to apply the design.

Limited Longevity: While iron-on transfers offer quick and easy customization, they may not be the best option for long-term use. Over time, the design may deteriorate or peel off, especially if the garment is frequently washed or exposed to harsh conditions.

Limited Professional Appeal: Iron-on transfers may not provide the same level of professionalism as other methods like embroidery or screen printing. While they are perfect for casual or personal use, if you are looking to create branded merchandise or professional-looking apparel, other methods may be more appropriate.

In conclusion, both heat transfer paper and iron-on transfers offer convenient and accessible methods for customizing fabric. The choice between the two depends on factors such as the desired durability, fabric color, complexity of the design, and budget. By understanding the differences and advantages of each method, you can make an informed decision on which technique best suits your specific needs.

Related:

Iron On Transfer Paper: pros and cons

The best heat transfer paper: Your Ultimate Guide for 2023