How to DIY Glass Jar/Cups with Sublimation Sticker Vinyl?

2023-11-10

Mastering Sublimation HTV on Cotton: Techniques and Tips

2023-11-17However, in this article, we will explore the process of sublimating heat transfer vinyl on cotton, including the materials needed, the steps involved, and some tips for achieving the best results.

Materials Needed

To sublimate heat transfer vinyl on cotton, you will need the following materials:

Cotton garment: Choose a cotton t-shirt, hoodie, or any other cotton fabric item on which you want to apply the heat transfer vinyl.

Sublimation Heat Transfer Vinyl: Select a sublimable heat transfer vinyl. It is crucial to choose vinyl specifically designed for sublimation as regular HTV vinyl will not work.

Sublimation Printer and Ink: You will need a sublimation printer and sublimation ink to print your design onto sublimation paper.

Sublimation Paper: Use sublimation paper to print your design. This special paper transfers the ink to the vinyl and then onto the fabric during the heat pressing process.

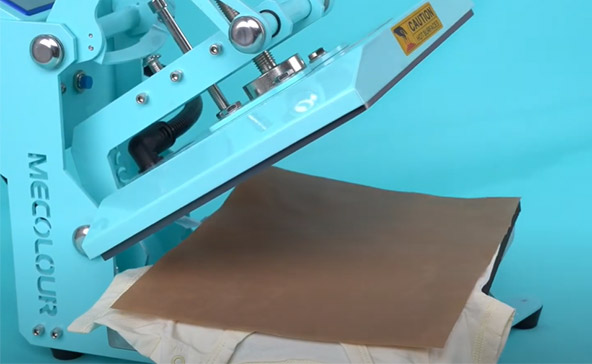

Heat Press Machine: A heat press machine is necessary to apply heat and pressure to transfer the sublimated vinyl design onto the cotton fabric.

transfer

Teflon Sheet or Parchment Paper: Place a teflon sheet or parchment paper between the heat press platen and the vinyl to protect the vinyl and fabric from scorching or sticking.

Heat Resistant Tape: Heat resistant tape is used to secure the sublimation paper and vinyl in place during the heat pressing process.

Cutting plotter or Scissors: You will need scissors or a cutting plotter to trim the excess vinyl.

Steps to Sublimate Heat Transfer Vinyl on Cotton

Follow these steps to successfully sublimate heat transfer vinyl onto cotton fabric:

Step 1: Design your artwork

Create or choose the design you want to transfer onto the cotton fabric. Make sure the design is compatible with sublimation printing and suitable for the size of your garment.

Step 2: Prepare the Design and Print

To start the process of transferring a pattern using sublimation heat transfer vinyl (HTV), you will need to obtain the desired pattern and import it into the operating software of a cutting plotter. Make sure the pattern is in the correct format and size for printing.

Next, set the print mode to “Mirror Print” to ensure that the design is mirrored when transferred onto the fabric. Use high-quality glossy paper suitable for sublimation printing, and select the standard print quality setting. Record the size settings of the printed pattern for reference.

Step 3: Cut Out the Pattern

Once the pattern is printed, re-upload it to the software of the cutting plotter. Ensure that the size of the pattern matches the printed version. Then, click on the “offset” option in the software and set the distance of the outline to 0.1mm. This offset will determine the cutting line for the pattern. Adjust the offset value accordingly if the pattern is complex or small.

Step 4: Prepare the Sublimation HTV Vinyl

Now, take out the sublimation heat transfer vinyl (HTV) and place it on the cutting plotter. Cut out the outline edge of the pattern using the cutting plotter, following the cutting line determined in the previous step. This will create a precise cutout of the pattern. Remember to set the cutting mode to “Mirror” to ensure that the design is cut in the correct orientation.

After cutting, carefully weed out the extra parts of the vinyl, leaving only the desired pattern on the carrier sheet. Take your time to remove any small pieces or intricate details.

Step 5: Transfer the Pattern onto Fabric

Prepare your heat press machine by setting the temperature to 185°C (365°F) and the pressure to medium.

Place the fabric on the heat press machine, ensuring it is flat and free from wrinkles. Then, position the sublimation HTV vinyl with the pattern facing up onto the fabric.

Apply heat and pressure by pressing the heat press machine down onto the vinyl and fabric. Follow the recommended heat press parameters of 185°C (365°F) and apply medium pressure. Press for approximately 5 seconds to adhere the vinyl to the fabric.

After the initial press, remove the base film of the sublimation vinyl while it is still warm (cold peel). Be careful not to peel off the pattern itself, only the excess vinyl.

Next, position the printed sublimation paper onto the sublimation vinyl, aligning it with the pattern. Make sure the paper is securely fixed in place.

Using the heat press machine, apply heat and pressure for a longer duration. Set the temperature to 185°C (365°F) and press for about 40 seconds. This process will transfer the ink from the sublimation paper to the vinyl and, subsequently, to the fabric.

After the pressing is complete, carefully peel off the sublimation paper while it is still cold (cold peel). This process reveals the transferred pattern on the fabric.

Once the transfer is complete, allow the fabric to cool down before handling or washing it. Follow any additional instructions provided by the sublimation HTV manufacturer for optimal results.

How to sublimate on cotton fabric with YESION Sublimation HTV Vinyl

By following these steps, you can successfully transfer a pattern onto fabric using sublimation heat transfer vinyl. Remember to always follow the recommended settings and instructions provided by the equipment and material manufacturers for the best results.

Tips for Best Results

Here are some additional tips to achieve the best results when sublimating heat transfer vinyl on cotton:

Choose high-quality materials: Ensure you use high-quality cotton garments and sublimation-compatible heat transfer vinyl. Using poor-quality materials may result in a less vibrant or less durable transfer.

Test before production: Before applying the design to your final garment, it is advisable to do a test run on a similar fabric. This helps you evaluate the colors, durability, and overall appearance of the transfer.

Follow manufacturer instructions: Always follow the instructions provided by the heat transfer vinyl manufacturer, including recommended temperature, pressure, and pressing time. These instructions may vary depending on the specific vinyl you are using.

Use a lint roller: Before pressing, use a lint roller to remove any lint, dust, or debris from the cotton fabric. This ensures a clean surface for the heat transfer vinyl.

Avoid stretching the fabric: Be careful not to stretch the fabric while positioning the sublimation paper and vinyl. Stretching can distort the design and affect the final result.

Practice proper heat press technique: When using the heat press machine, make sure to apply even pressure across the entire design. Uneven pressure can lead to inconsistent results.

Wash and care instructions: After sublimating the heat transfer vinyl onto the cotton fabric, it is important to follow the washing and care instructions provided by the heat transfer vinyl manufacturer. This ensures the longevity of the transfer.

By following these steps and tips, you can successfully sublimate heat transfer vinyl onto cotton fabric. This technique allows you to create vibrant, full-color designs on cotton garments, adding a personalized touch to your clothing or promotional items.