Specificaltions

| Surface material | PU face film |

| Film thickness(with glue) | 0.14mm |

| Glue type | Silica glue |

| Release paper | PET |

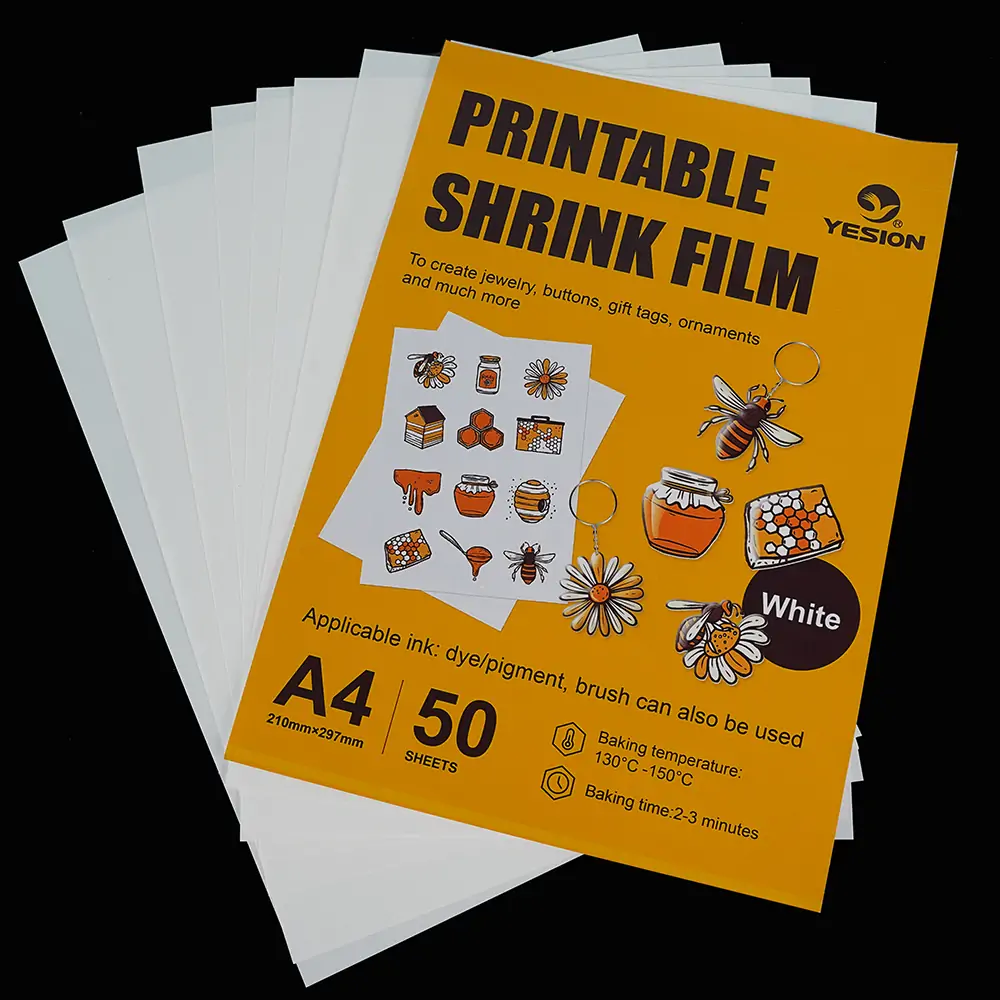

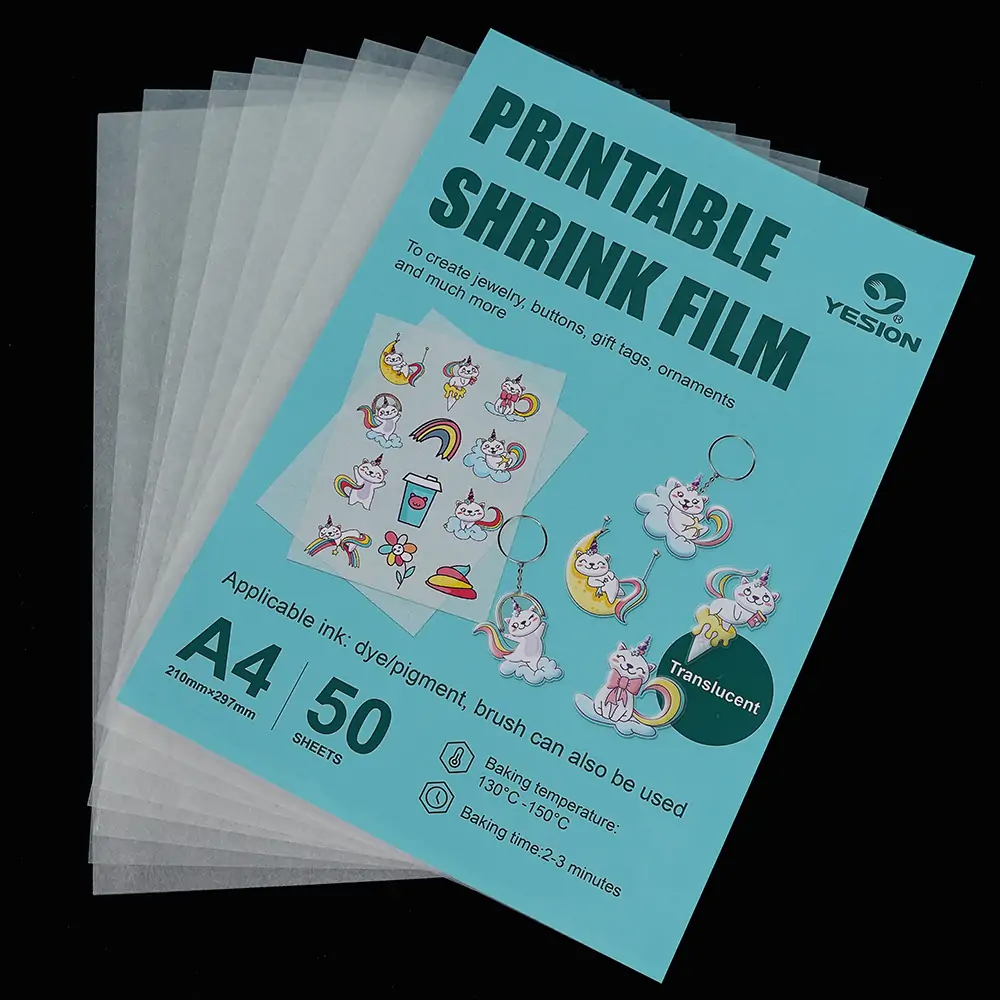

| Color | White |

| Available sizes | A4/A3/12inX12in/12inx82ft |

Opertation and Video

Materials needed:

Computer, printer, Sublimation ink, Cutting plotter, Tool set, Heat press machine,black fabric.

Opertation:

Step 1:

Obtain a pattern, import the pattern into the operating software of the cutting plotter, and print the designed pattern with sublimation ink through the software of the cutting plotter.

Print Mode: Mirror Print, High Quality Glossy Paper, Standard Print Quality.

Note: Record the size settings of the printed pattern.

Step 2:

Re-upload the pattern to the software of the cutting plotter (Note: The size of the pattern needs to be the same as the printed pattern), then click the offset and set the distance of the outline to 0.1mm and cut out the pattern (if the pattern is complex and small, the offset can be appropriately increased; if it is simple and the offset can be appropriately reduced).

Take out the sublimation vinyl, cut out the outline edge of the pattern by the cutting plotter, and then weed the extra parts. (Note: Cutting Mode:Mirror).

Step 3:

Transfer the pattern.

Set heat press parameters: Temperature: 185℃, Pressure: medium.

Put the sublimation HTV vinyl face up on the fabric, iron at 185℃ for 5 seconds, and remove the base film of the sublimation vinyl (Cold Peel).

Put the printed sublimation paper on the sublimation vinyl,Align and fix the pattern.Iron with a heat press machine at 185°C for 45 seconds, peel off the sublimation paper(cold peel).

Step 4:

Transfer completed.

Note: If the pattern is not easy to align during transfer, you can also put a positioning film on the back of the sublimation paper, and then use a cutting plotter to cut the pattern on the sublimation paper and then weed the extra parts,in order to align the pattern during transfer.

Application

Sublimation HTV vinyl is widely used on most material: 100% Cotton, 100% Polyester, Poly / Cotton Blends,such as dark colored clothes, Canvas bags, Hats, Socks, Pillows, Baby clothing and more.